6/10/14

The US Congress mandated through the Clean Water Act

The US Congress mandated through the Clean Water Act, that the US EPA would keep a list of products that may be legally used on US Navigable waters Oil Spill Eater II is on this NCP list

The EPA requires certain disclosures in regards to a product listing, and these requirements have been met with confusion even by other US departments, so the OSEI Corporation wants to have full disclosure of the law/regulations, the OSE II listing letter, the information maintained by the US EPA on their notebook, and the how to get on the list information for all to see.

Subpart J—Use of Dispersants andOther Chemicals

SOURCE: 59 FR 47453, Sept. 15, 1994, unless otherwise noted.

§ 300.900 General.

- Section 311(d)(2)(G) of the CWA requires that EPA prepare a schedule of dispersants, other chemicals, and other spill mitigating devices and sub‐stances, if any, that may be used in carrying out the NCP. This subpart makes provisions for such a schedule.

- This subpart applies to the navigable waters of the United States and adjoining shorelines, the waters of the contiguous zone, and the high seas beyond the contiguous zone in connection with activities under the Outer Continental Shelf Lands Act, activities under the Deepwater Port Act of 1974, or activities that may affect natural resources belonging to, appertaining to, or under the exclusive management authority of the United States, including resources under the Magnuson Fishery Conservation and Management Act of 1976.

- This subpart applies to the use of any chemical agents or other additives as defined in subpart A of this part that may be used to remove or control oil discharges.

§ 300.905 NCP Product Schedule.

- Oil Discharges. (1) EPA shall maintain a schedule of dispersants and other chemical or bioremediation products that may be authorized for use on oil discharges in accordance with the procedures set forth in § 300.910. This schedule, called the NCP Product Schedule, may be obtained from the Emergency Response Division (5202–G), U.S. Environmental Protection Agency, 1200 Pennsylvania Ave., NW., Wash‐ington, DC 20460. The telephone number is 703–603–8760.(2) Products may be added to the NCP Product Schedule by the process specified in § 300.920.

- Hazardous Substance Releases. [Re‐served]

[59 FR 47453, Sept. 15, 1994, as amended at 65 FR 47325, Aug. 2, 2000] § 300.91

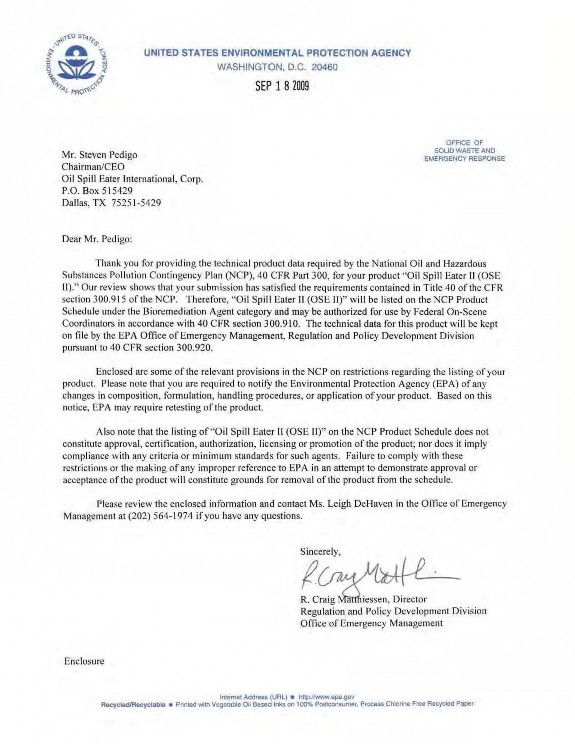

OIL SPILL EATER LISTING OF OSE II ON THE US EPA NCP LIST

LETTER

OIL SPILL EATER II TECHNICAL INFORMATION IN THE US EPA NOTEBOOK

LINK http://www2.epa.gov/emergency-response/oil-spill-eater-ii

LINK http://www2.epa.gov/emergency-response/oil-spill-eater-ii

Emergency Management

Contact Us Search: All EPA Emergency Management

Home

You are here: EPA HomeEmergency ManagementNCP Subpart J

NCP Product Schedule

![]()

OIL SPILL EATER II

OIL SPILL EATER II

TECHNICAL PRODUCT BULLETIN #B-53 USEPA, OFFICE OF EMERGENCY MANAGEMENT

REGULATION AND POLICY DEVELOPMENT DIVISION

ORIGINAL LISTING DATE: AUGUST 26, 1996

REMOVAL DATE: AUGUST 16, 2005

RELISTING DATE: SEPTEMBER 18, 2009 “OIL SPILL EATER II (OSE II)”

- NAME, BRAND, OR TRADEMARKOIL SPILL EATER II (OSE II)Type of Product: Bioremediation Agent (Biological Enzyme Additive [previously listed as a Nutrient Additive])

- NAME, ADDRESS, AND TELEPHONE NUMBER OF MANUFACTURER/CONTACTOSEI Corporation (Formerly Sky Blue Chems)P.O. Box 515429

Dallas, TX 75251-5429

Phone: (972) 669-3390

E-mail: oseicorp@msn.com

Web Site: www.osei.us

(Mr. Steven Pedigo, Chairman, CEO, Inventor)

- NAME, ADDRESS, AND TELEPHONE NUMBER OF PRIMARY DISTRIBUTORSOSEI Corporation (Formerly Sky Blue Chems)P.O. Box 515429

Dallas, TX 75251-5429

Phone: (972) 669-3390

E-mail: oseicorp@msn.com

Web Site: www.osei.us

(Mr. Steven Pedigo, Chairman, CEO, Inventor)

- SPECIAL HANDLING AND WORKER PRECAUTIONS FOR STORAGE AND FIELD APPLICATIONº

- Flammability: Water-based, non-flammable

- Ventilation: Needs no ventilation; aqueous-based product; does not emit hazardous vapors

- Skin and eye contact; protective clothing; treatment in case of contact: OSE II is not a primary dermal irritant. Avoid eye contact, and wear goggles if possible for the spray to come in direct contact with eyes.Facilities for quick and copious eye flushing should be provided and prompt medical attention should besought if exposure and irritation persists. Protective rubber gloves are suggested during handling. Before mixing the product has a smell of fermentation. The product does not give off any harmful vapors.

- a. Maximum storage temperature: 120ºF

- Minimum storage temperature: None; OSE II can freeze and thaw without adverse effects

- Optimum storage temperature range: 72ºF

- Temperatures of phase separations and chemical changes: 120ºF

- SHELF LIFEOSE II has a recommended shelf life of 5 years. After 5 years at optimum storage temperature, there is an approximate 10% decrease per year in product capability.

- RECOMMENDED APPLICATION PROCEDURE

1. Application Method: A. Use surface spray apparatus, such as small hand held tanks, back pack, large mixing tanks with mechanical pumping devices, vessels with booms for spraying wide paths, or spray devices on airplanes or helicopters. B. OSE II can be applied by eductor systems from vessels, fire trucks, etc. Set the eductor system to 2% and apply 1 gallon of mixed OSE II to each spilled gallon of hydrocarbon. - Concentration/Application Rate:General – OSE II generally takes 3 to 30 minutes to penetrate the molecular walls of hydrocarbons. However, once you spray OSE II on the hydrocarbons, OSE II attaches itself and will eventually engulf the hydrocarbons regardless of where the hydrocarbons may spread on the surface of salt or fresh water. Additionally, once you spray OSE II, the hydrocarbons cannot attach itself to the shoreline, rocks, or any equipment in its path. OSE II breaks down the adhesion properties of hydrocarbons and causes hydrocarbons to float, thereby, eliminating secondary contamination of the water column or any other areas, and holding the contaminated area to the waters surface, the original contaminated area.If OSE II is to be used on ocean spills or on intertidal zones OSE II should be mixed with ocean water.

If OSE II is to be used on lakes, rivers, streams, ponds, or on land mix the product with water

from a lake, stream, or pond.

If you are performing a clean up, make sure the water used to mix with OSE II, and the water used to keep the area saturated, is the type of water normally associated with that area.

If you use fresh water in an area normally contacted with salt water or vice versa, the different

types of bacteria and competition could occur, not to mention the problems with salinity for fresh water organisms.

[Note: Do not mix tap water with OSE II if possible: Chlorine in tap water slows bacterial enhancement]

Spills on Water:

Dilute each gallon of OSE II with 50 gallons of fresh, brackish, or salt water – depending on the water associated with the area that has been impacted by the spill. Apply OSE II at a ratio of 1 gallon mixed OSE II to each gallon of hydrocarbon spilled. Apply using hand held sprayers, tank sprayers, booms from vessels, helicopters, or airplanes; by spraying the perimeter first then working toward the middle of the spilled area. Next spray the entire surface of the spill. If the spill is very heavy (more than 2 inches thick) it is recommended that OSE II be applied every day until you have met a 1:1 ratio of OSE II and water mixture to spilled oil/hydrocarbons.

Use 1 gallon OSE II for every 50 gallons of hydrocarbons.

Use 1 drum of OSE II for every 2,750 gallons of hydrocarbons.

If you know gallons of hydrocarbons spilled, multiply gallons of hydrocarbons by 0.02 to get amount of OSE II needed [gallons of hydrocarbons x 0.02 = gallons of OSE II].

If you know barrels of crude oil spilled, multiply barrels of crude oil by 0.015 to get drums of OSE

II needed [barrels of crude oil x 0.015 = drums of OSE II].

If you do not know gallons of hydrocarbons or barrels of crude oil, multiply size of spill by 0.0023 to get drums of OSE II needed or by 0.12 to get gallons of OSE II needed [(yards long x yards

wide x inches thick) x 0.0.0023 = drums of OSE II or (yards long x yards wide x inches thick) x

0.015 = gallons of OSE II].

Intertidal Zone: Mix each 55 gallon drum of OSE II with 2,750 gallons of fresh, brackish, or salt water. The water used is determined by the type of water associated with the site. OSE II should be applied as the tide recedes (if there is a tide) and once the tide comes in the application should cease until the tide recedes again. Additional applications should only be warranted if spill has been allowed time to percolate into the depths of the soil. If there is no tide, but waves have pushed the spill into the intertidal zone, then there will be direct access to the spill at all times. If possible use string or stakes to grid off the beach or intertidal zone area, and then you can calculate how much premixed OSE II to apply to a given area. If unable to grid off an area then calculate how much OSE II to apply and then determine how much premixed OSE II will flow through a nozzle (gallons per minute) then let application technician know how many gallons to apply in a given area and this can be determined by applying product for a certain time period to get the correct amount of OSE II applied to gain the 1:1 ratio.

Note: If the intertidal zone is associated with the sea then mix OSE II with salt water. If the spill area is in an area of brackish water then mix OSE II with brackish water. If the intertidal zone is associated with fresh water such as lakes, rivers, streams, ponds, creeks, aquifers, or drinking water wells then use fresh water to mix OSE II. - Conditions for Use:

OSE II can remediate hydrocarbon-based material including chlorinated hydrocarbons, PCB’s, dioxins, and some pesticides.

As the age of spilled hydrocarbons increases, the time necessary for bioremediation increases. In

general, fresh crude, gasoline of BTEX takes from 72 hours to 30 days to completely bioremediate.

Variations of sea water salinity should have no effect, but as long as microbial life can exist, then OSE II will be effective.

OSE II bioremediation slows somewhat at temperatures below 40ºF. OSE II however, will continue to work at any liquid water temperature that will sustain microbial life.

- Concentration/Application Rate:General – OSE II generally takes 3 to 30 minutes to penetrate the molecular walls of hydrocarbons. However, once you spray OSE II on the hydrocarbons, OSE II attaches itself and will eventually engulf the hydrocarbons regardless of where the hydrocarbons may spread on the surface of salt or fresh water. Additionally, once you spray OSE II, the hydrocarbons cannot attach itself to the shoreline, rocks, or any equipment in its path. OSE II breaks down the adhesion properties of hydrocarbons and causes hydrocarbons to float, thereby, eliminating secondary contamination of the water column or any other areas, and holding the contaminated area to the waters surface, the original contaminated area.If OSE II is to be used on ocean spills or on intertidal zones OSE II should be mixed with ocean water.

- TOXICITY AND EFFECTIVENESSa. Effectiveness: Summary Data Table:

DAYS PRODUCT3 REPS/PROD TOTAL MEAN ALKANES (ppm) RED% 28 DAYS TOTAL MEAN AROMATICS (ppm) RED% 28 DAYS 0 CONTROL 43,170 – 11,435 – NUTRIENT 40,569 – 11,785 – OSE II 41,730 – 12,155 – CONTROL 39,250 9.1 10,355 9.4 7 NUTRIENT 34,815 14.2 9,898 16.0 OSE II 26,316 36.9 8,072 33.6 CONTROL 35,797 17.1 9,534 16.6 28 NUTRIENT 26,507 34.7 8,938 24.2 OSE II 4,273 89.8 1,268 89.6 Results of Gravimetric Analysis:

Percentage (%) Decrease in Weight of Oil on Day 28 Control: 16.5%

Nutrient: 52.0%

Product: 85.4%

- MICROBIOLOGICAL ANALYSIS

- Listing of each component of the total formulation, other than enzymes, by chemical name and percentage by weight: CONFIDENTIAL

- Enzyme Names: CONFIDENTIAL

- I.U.B.: CONFIDENTIAL

- Source of Enzymes: Fermentation process

- Units: No less than 1% and no more than 50% by weight

- Specific Gravity: 1.05

- Optimum Conditions:

- pH: 7.0

- Temperature: 72ºF

- Salinity Ranges: Fresh water to salt water

- Maximum and Minimum pH: 3.5 – 8.0

- Maximum and Minimum Temperature: 28ºF – 128ºF

- Maximum and Minimum Salinity Levels – Salinity level above that will support microbial activity will adversely effect OSE II’s performance

- Enzyme Shelf Life: Up to 5 years when properly stored

- Enzyme Optimal Storage Conditions: 72ºF is optimal, enzyme range is freezing to 120ºF, never leave OSE II in direct sunlight for more than a couple of hours

- PHYSICAL PROPERTIESNA

- ANALYSIS OF HEAVY METALS, CYANIDE, AND CHLORINATED HYDROCARBONS

NA

How to get a product on the US EPA NCP list

http://www2.epa.gov/emergency‐response/national‐contingency‐plan‐subpart‐j#howto

Emergency Response National Contingency Plan Subpart J

One of EPA’s top priorities is to prevent, prepare for, and respond to oil spills that occur in and around inland waters of the United States. EPA is the lead federal response agency for oil spills occurring in inland waters. The U.S. Coast Guardis the lead response agency for spills in coastal waters and deepwater ports. Subpart J of the National Oil and HazardousSubstances Pollution Contingency Plan (NCP) directs EPA to prepare a schedule of dispersants, other chemicals, and oil spill mitigating devices and substances that may be used to remove or control oil discharges.

NCP Product Schedule

Environmental Monitoring for Atypical Dispersant Operations: Including Guidance for Subsea Application andProlonged Surface Application Revisions to Subpart J of the NCP under Consideration

NCP Product Schedule Technical Notebook How to List a New Product on the NCP Product Schedule

NCP Subpart J Regulations Effectiveness and Toxicity Testing Disclaimer Information For More Information

The NCP Product Schedule (April 2014) (PDF) is also available for download in its entirety.

EPA maintains the NCP Product Schedule, which lists the following types of products that are authorized for use on oil discharges:

Bioremediation agents Dispersants Surface washing agents Surface collecting agents Miscellaneous oil spill control age See Definitions of Product Categories See Alphabetical List of NCP Product Schedule Products with Links to Technical Product Summaries

Design for the Environment

Note: Products may be eligible for recognition by EPA’s Design for the Environment (DfE) Program as a safer oil spill treatment. The DfE Program labels products that have met its stringent criteria for human health and environmental safety.

NCP Product Schedule Technical Notebook

The NCP Product Schedule Technical Notebook (April 2014) (PDF) presents manufacturer’s summary information on the conditions under which each of the products is recommended to be used. Manufacturer information may provide handling and worker precautions, storage information, recommended application procedures, physical properties, and toxicity, effectiveness, or other analyses.

Disclaimer: The listing of a product on the Product Schedule does NOT mean that EPA approves, recommends, licenses,

certifies, or authorizes the use of the product on an oil discharge. The listing means only that data have been submitted to EPA as required by Subpart J of the National Contingency Plan, Section 300.915. (Source: 40 CFR § 300.920 (e)) There is an established process that manufacturers must follow to have a product listed on the NCP Product Schedule.

Begin by reviewing data requirements in section 300.915 of Subpart J of the NCP Product Schedule.

Determine product category (e.g., dispersant, surface washing agent, etc.)

Fulfill each of the data requirements for selected product category, including effectiveness and toxicity testing (if applicable). If you need assistance locating a laboratory to help fulfill these requirements, please call the NCPProduct Schedule Information Line.

Send a hard copy of all data requirements for review to: NCP Product Schedule Manager U.S. Environmental Protection Agency Ariel Rios North Building – Mail Code 5104-A Room 6450T Washington, D.C. 20460

If you have further questions or require more information, please call the NCP Product Schedule Information Line.

Subpart J Regulations

EPA is currently making revisions to the Subpart J regulation to clarify and update the Product Schedule listing procedures. These updates may include effectiveness and toxicity testing. Once the proposed rule is posted to the docket, there will be a public comment period for providing questions and concerns. The compiled comments will be addressed in the final rule. Office of Management and Budget Agenda: Revisions to the National Oil and Hazardous SubstancesPollution Contingency Plan; Subpart J Product Schedule Listing Requirements.

NCP Subpart J: Use of Dispersants and Other Chemicals – 40 CFR 300.900 – 300.920 (PDF)NCP: Definitions – 40 CFR 300.5 (PDF)

Relevant Federal Register Notices

Effectiveness and Toxicity Testing

For the products on the schedule, EPA provides NCP Product Schedule Toxicity and Effectiveness Summaries for each product category. Appendix C to 40 CFR part 300 describes methods for required effectiveness and toxicity tests for specific product categories. See: 40 CFR part 300 Appendix C | PDF (22 pp, 284 K, About PDF)

The listing of a product on the NCP Product Schedule does not constitute approval of the product. To avoid possible

misinterpretation or misrepresentation, any label, advertisement, or technical literature that refers to the placement of the product on the NCP Product Schedule must either reproduce in its entirety EPA’s written statement that it will add the product to the NCP Product Schedule under Sec. 300.920(a)(2) or (b)(2), or include the disclaimer shown below. If the disclaimer is used, it must be conspicuous and must be fully reproduced. Failure to comply with these restrictions or any other improper attempt to demonstrate the approval of the product by any National Response Team (NRT) or other U.S. Government agency shall constitute grounds for removing the product from the NCP Product Schedule. [40 CFR 300.920(e)]

[PRODUCT NAME] is on the U.S. Environmental Protection Agency’s NCP Product Schedule. This listing does NOT mean

that EPA approves, recommends, licenses, certifies, or authorizes the use of [PRODUCT NAME] on an oil discharge. This listing means only that data have been submitted to EPA as required by subpart J of the National Contingency Plan, Sec. 300.915.

The US Congress required the US EPA to keep a list of products that can be legally used on US Navigable waters, which is why there is a an NCP list.

Excerpt Sections from the Complete Technical Library

Company History

Note to Contractors

Introduction

General Description

Chemical Process

Emulating Mother Nature

The US Congress mandated through the Clean Water Act

How to get a product on the US EPA NCP list

U.S. EPA NCP Letter Listing OSE II

US EPA notebook with technical information on OSE II highlighted section vI-1

Bioaquatic Lab Testing

U.S. EPA Regulation regarding the use of OSE II

OSE II in Storm Water Drains or U.S. Navigable Waters

MSDS on OSE II

OSHA Letter